Timber frame construction in the UK , Ireland and other countries is based on factory-made structural elements. The timber framed wall panels carry the loads on the building to the foundations whilst the outer wall provides decoration and weather protection. The outer wall is a matter of choice; it can be brick, stone or lightweight claddings, such as timber boarding, tile hanging or render.

Factory production of the timber frame panels ensures that they are accurately manufactured to precise tolerances in a controlled environment away from the variants of Bulgarian cold winters and hot summer.

The timber frame panels are rapidly erected on site and, with cut rafters forming the roof, a weathertight building can be created in a matter of days. This enables work to continue in protected conditions within the building whilst the outer cladding and roof finishes are applied.

Timber frame is not just for houses; it is being used extensively for flats, schools, hotels, offices and sports facilities. Buildings up to five storeys high can be constructed and, like all methods of construction, conform to the requirements of the Building Regulations.

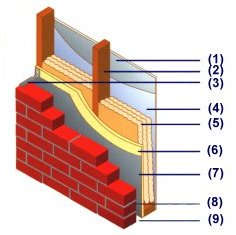

Timber frame wall panels are made up of softwood vertical studs and horizontal rails with a wood-based panel sheathing and a plasterboard lining. The studs carry vertical loads through the structure and transfer them to the foundations. The sheathing provides resistance to lateral wind loads (known as racking resistance). Thermal insulation is usually incorporated in the spaces between the studs of external walls and protective membrane materials may also be required, depending on the design of the wall. For all external walls a breather membrane on the external face of the panels protects the panels during construction. This also allows the timber to breath and protects the panels from any moisture that may be in the cavity. A vapour control layer in the form of polythene sheet or plasterboard with an integral vapour control layer is normally required on the 'warm' side of the insulation, behind the plasterboard lining to limit the amount of water vapour entering the wall panel.

Timber is recognized as the only renewable construction material and the softwoods used in timber frame are sourced from environmentally sustainable European forests. The timber frame method of building gives designers flexibility in both layout and external appearance. High levels of thermal insulation are incorporated within the construction, reducing heating costs and conserving energy. Dry construction not only saves time on site but means that decorations can be carried out soon after completion of the building without risk of cracking and deterioration of finishes.

1. Inner lining of plasterboard

2. Structural Timber frame

3. Stainless steel wall tie

4. Vapour check

5. Thick insulation

6. OSB sheating board

7. Waterproof breather membrane

8. 50 mm wall cavity

9. Brick outer cladding

Most timber frame buildings in the UK, Ireland and other countries are built using prefabricated panels produced by specialist companies like Global Structures LTD.